FAQ

news center

Contact us

-

E-mail: sales@handif.com info@handif.com

Telephone:+86 0755-27448120

24-hour service call:+86 13632652467

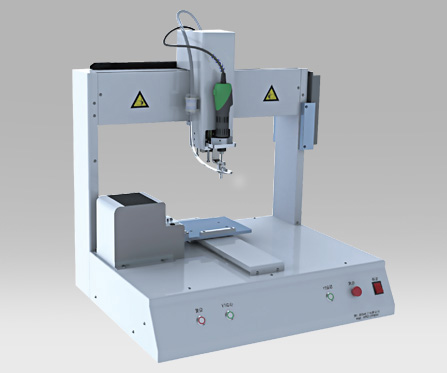

Desktop lock screwing machine also known as : lock screwing robot,automatic screw tightening machine,automatic lock screwing machine

also known as : lock screwing robot,automatic screw tightening machine,automatic lock screwing machine

Single station automatic lock screw machine (suction type)

Product introduction

Performance parameters

|

Power source / gas source |

220V AC 50Hz / 0.4~0.6Mpa |

|

Automatic screwdriver parameter |

0.2~3.5、0.5~7、1~10、1.5~12、3~17 (According to different screwdrivers, optional adjustable torque) |

|

Air suction screw supply machine parameters |

M1.0、M1.2、M1.4、M1.7、M2.0、M2.3、M2.6、M3.0 Optional (according to customer's screw) |

|

Motor control shaft number |

Three axis |

|

Adapt to the specification of the locking product |

320×280×60mm(X×Y×Z)Locked-in hole<20mm(Parts need to be replaced) |

|

Axial range |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Axial velocity |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Repeat position accuracy |

X axis ±0.05 mm、Y axis ±0.05 mm、Z axis ±0.05 mm

|

|

Resolution |

X axis 0.01 mm、Y axis 0.01 mm、Z axis 0.01 mm |

|

Load weight |

Workbench 6 Kg, Machine 3 Kg |

|

Control speed mode |

Speed can be set |

|

Teaching document capacity |

128M (120 files, 64 points/file) |

|

Control and programming methods |

Motion controller + touch screen + teaching mode |

|

Applicable environment |

Temperature 0 ~ 40 °, humidity 20% ~ 90% |

|

Dimensions |

630×528×680mm(L×W×H) |

|

weight |

About 70kg |

Double-station automatic locking screw machine (inflatable)

Product introduction

Performance parameters

|

Power source / gas source |

220V AC 50Hz / 0.4~0.6Mpa |

|

Automatic screwdriver parameter |

0.2~3.5、0.5~7、1~10、1.5~12、3~17 (According to different screwdrivers, optional adjustable torque) |

|

Air suction screw supply machine parameters |

M1.0、M1.2、M1.4、M1.7、M2.0、M2.3、M2.6、M3.0 Optional (according to customer's screw) |

|

Motor control shaft number |

Three axis |

|

Adapt to the specification of the locking product |

320×280×60mm(X×Y×Z)Locked-in hole<20mm(Parts need to be replaced) |

|

Axial range |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Axial velocity |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Repeat position accuracy |

X axis ±0.05 mm、Y axis ±0.05 mm、Z axis ±0.05 mm |

|

Resolution |

X axis 0.01 mm、Y axis 0.01 mm、Z axis 0.01 mm |

|

Load weight |

Workbench 6 Kg, Machine 3 Kg |

|

Control speed mode |

Speed can be set |

|

Teaching document capacity |

128M (120 files, 64 points/file) |

|

Control and programming methods |

Motion controller + touch screen + teaching mode |

|

Applicable environment |

Temperature 0 ~ 40 °, humidity 20% ~ 90% |

|

Dimensions |

630×528×680mm(L×W×H) |

|

weight |

70Kg |

Double-station automatic locking screw machine (inflatable)

Product introduction

|

Power source / gas source |

220V AC 50Hz / 0.4~0.6Mpa |

|

Automatic screwdriver parameter |

0.2~3.5、0.5~7、1~10、1.5~12、3~17 (According to different screwdrivers, optional adjustable torque) |

|

Air suction screw supply machine parameters |

M1.0、M1.2、M1.4、M1.7、M2.0、M2.3、M2.6、M3.0 Optional (according to customer's screw) |

|

Motor control shaft number |

Three axis |

|

Adapt to the specification of the locking product |

320×280×60mm(X×Y×Z)Locked-in hole<20mm(Parts need to be replaced) |

|

Axial range |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Axial velocity |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Repeat position accuracy |

X axis ±0.05 mm、Y axis ±0.05 mm、Z axis ±0.05 mm |

|

Resolution |

X axis 0.01 mm、Y axis 0.01 mm、Z axis 0.01 mm |

|

Load weight |

Workbench 6 Kg, Machine 3 Kg |

|

Control speed mode |

Speed can be set |

|

Teaching document capacity |

128M (120 files, 64 points/file) |

|

Control and programming methods |

Motion controller + touch screen + teaching mode |

|

Applicable environment |

Temperature 0 ~ 40 °, humidity 20% ~ 90% |

|

Dimensions |

630×528×680mm(L×W×H) |

|

weight |

About 70kg |

Double-station automatic locking screw machine (inflatable)

Product introduction

(Double-station double supply automatic lock screw machine )

|

Power source / gas source |

220V AC 50Hz / 0.4~0.6Mpa |

|

Automatic screwdriver parameter |

0.2~3.5、0.5~7、1~10、1.5~12、3~17 (According to different screwdrivers, optional adjustable torque) |

|

Air suction screw supply machine parameters |

M1.0、M1.2、M1.4、M1.7、M2.0、M2.3、M2.6、M3.0 Optional (according to customer's screw) |

|

Motor control shaft number |

Three axis |

|

Adapt to the specification of the locking product |

320×280×60mm(X×Y×Z)Locked-in hole<20mm(Parts need to be replaced) |

|

Axial range |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Axial velocity |

X axis 0.1~800 mm/s、Y axis 0.1~800 mm/s、Z axis 0.1~500 mm/s |

|

Repeat position accuracy |

X axis ±0.05 mm、Y axis ±0.05 mm、Z axis ±0.05 mm |

|

Resolution |

X axis 0.01 mm、Y axis 0.01 mm、Z axis 0.01 mm |

|

Load weight |

Workbench 6 Kg, Machine 3 Kg |

|

Control speed mode |

Speed can be set |

|

Teaching document capacity |

128M (120 files, 64 points/file) |

|

Control and programming methods |

Motion controller + touch screen + teaching mode |

|

Applicable environment |

Temperature 0 ~ 40 °, humidity 20% ~ 90% |

|

Dimensions |

630×528×680mm(L×W×H) |

|

weight |

About 70kg |

E-mail: sales@handif.com info@handif.com

Telephone:+86 0755-27448120

24-hour service call:+86 13632652467

深圳市汉迪丰科技有限公司 版权所有 ICP备案编号:粤ICP16001872号-3