FAQ

news center

Contact us

-

E-mail: sales@handif.com info@handif.com

Telephone:+86 0755-27448120

24-hour service call:+86 13632652467

Laser micro-cladding also called laser direct write, mainly for the manufacture of microelectronic components. The process of electronic paste and other functional materials as cladding material, and use continuous or pulsed laser irradiation, make the cladding material interior, cladding layer and substrate interface physical and chemical effects, forming the wire, functional components or MEMS microstructure what will need.

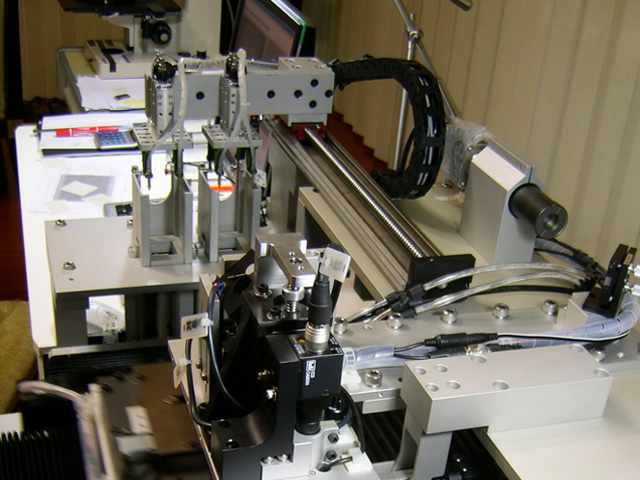

Laser micro-cladding machine

Product introduction

The basic principle and characteristics of laser micro-cladding:

The basic principle of the laser micro-cladding technique is make the functional material (such as micron and nanoscale powders or slurries) on the functional substrate (glass, ceramic, organic epoxy board, plastic, Silicon and other non-metallic materials)by miscro pens or micro-jet and other deposition methods ,then use the special software and combined with CAD / CAM,transform the graphics file to processing documents directly and quickly.Control the laser walking path, deal with the functional powder or slurry layer, make the cladding material interior, cladding layer and substrate interface physical and chemical effects,getting the different width wire and passive components,it achieved to prepare the conductive layer, resistance layer and media layer on insulation substrate surface directly under the maskless mold.

Laser micro-cladding’s feature is can clad all kinds of functional electronic and semiconductor or insulator paste on all kinds of electronic, semiconductor substrate surface ,forming the functional coating what it need.It can achieve to manufacture (micro) electronic components, optoelectronic devices, hybrid integrated circuit substrate, MEMS quickly .Its processing accuracy is high,good quality,easy to achieve flat and three-dimensional processing,high degree of flexibility,wide application range of substrate.the market expectation is very vast on electronic manufacturing, precision machinery and bioengineering.

Performance parameters

|

Way of working |

Accurate continuous |

|

Power configuration (optional) |

0~50W |

|

Laser wavelength (optional) |

355nm、532nm、1.064mm |

|

Micro pen write the minimum width |

≤60μm |

|

Micro-jet write the minimum width |

≤20μm |

|

Micro-jet / micro-pens - Lasercompound micro-cladding minimum line width |

≤10μm |

|

Repeatability |

±0.001mm |

|

Table size (optional) |

Standard countertops:400mm×300mm×100mm |

|

Positioning |

CCD positioning, with automatic zoom compensation. |

|

Support processing file format |

AutoCAD, Protel, Gerber |

|

stability |

24 hours of continuous work without failure. |

E-mail: sales@handif.com info@handif.com

Telephone:+86 0755-27448120

24-hour service call:+86 13632652467

深圳市汉迪丰科技有限公司 版权所有 ICP备案编号:粤ICP16001872号-3